Abrasion Resistant Materials and Wear Strips

Solutions for Unmatched Protection and Durability

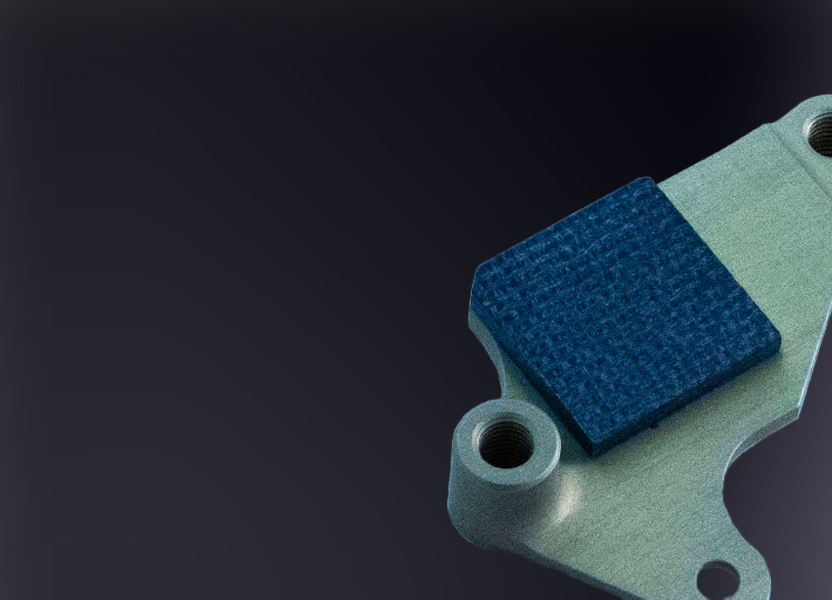

We offer high-performance abrasion-resistant P54 and KAron wear strips, specifically engineered to prevent metal-to-metal wear and fretting damage caused by sliding or rubbing surfaces. These products deliver an exceptional layer of defense against wear, ensuring the longevity of the items they protect.

Wear Strips

Kamatics Wear Strips are designed to be bonded onto surfaces as a protective barrier and are available in standard sizes or custom-cut profiles.